Die casting expertise since 1949

Quality, innovation and precision for industrial applications

Production departments

Our departments

Foundry

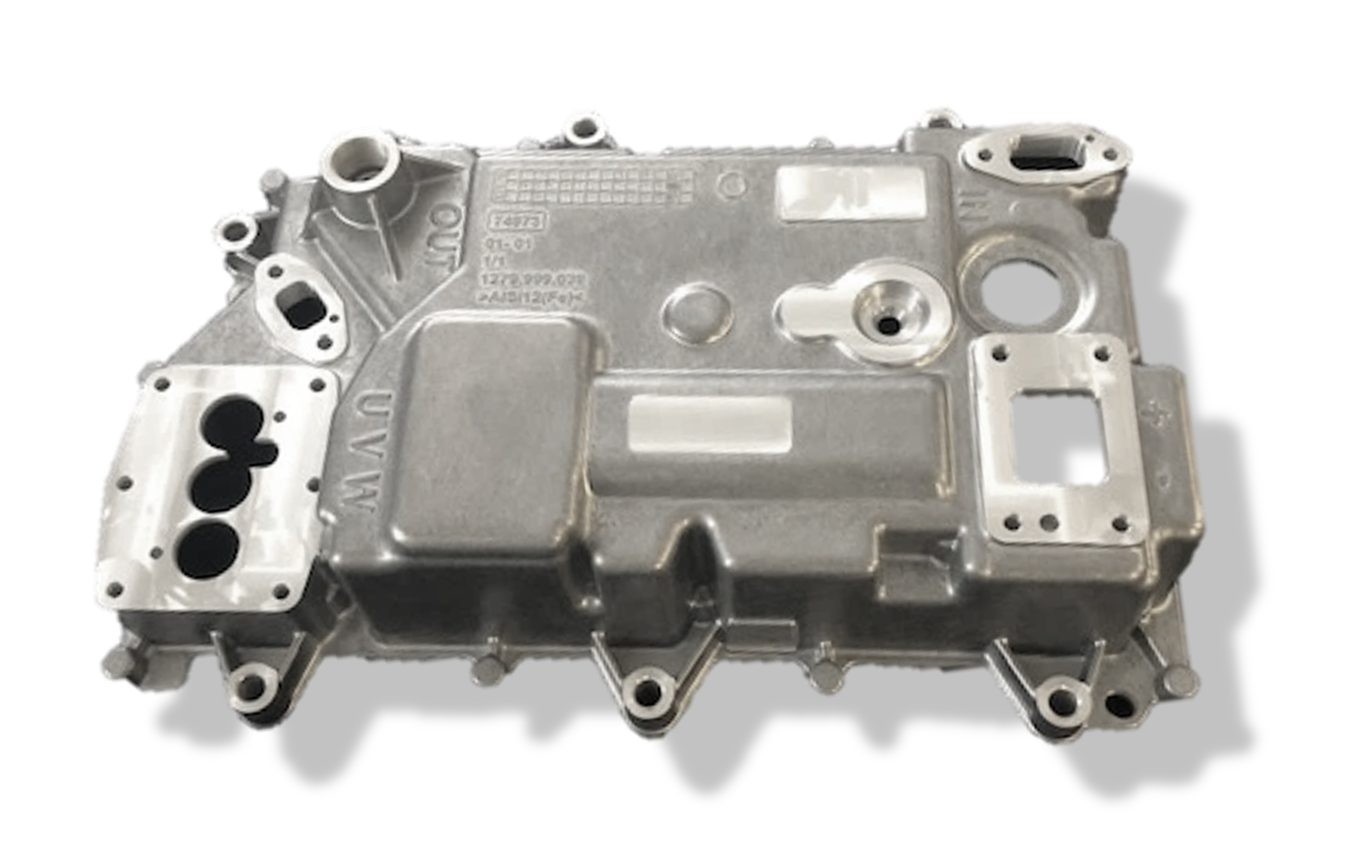

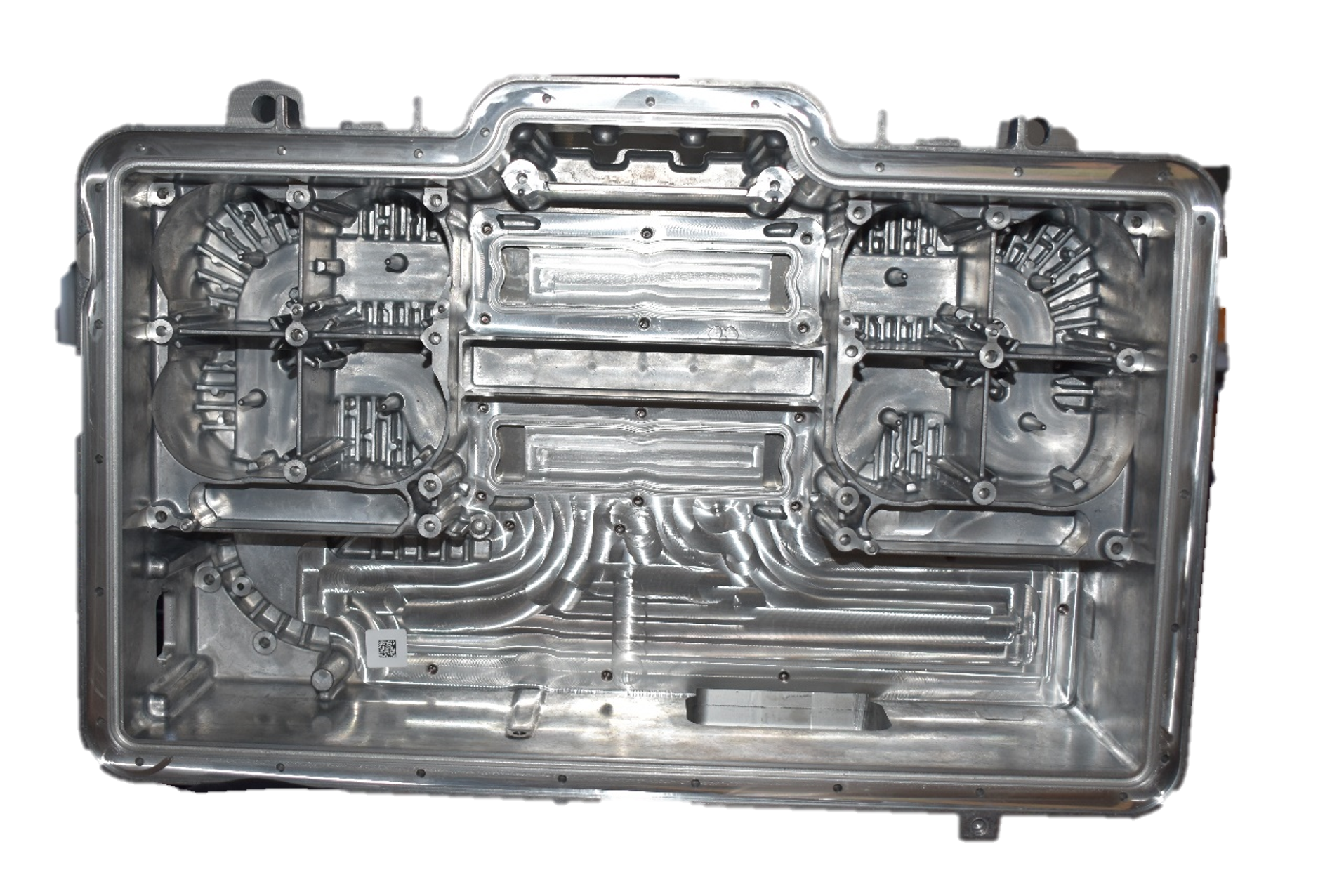

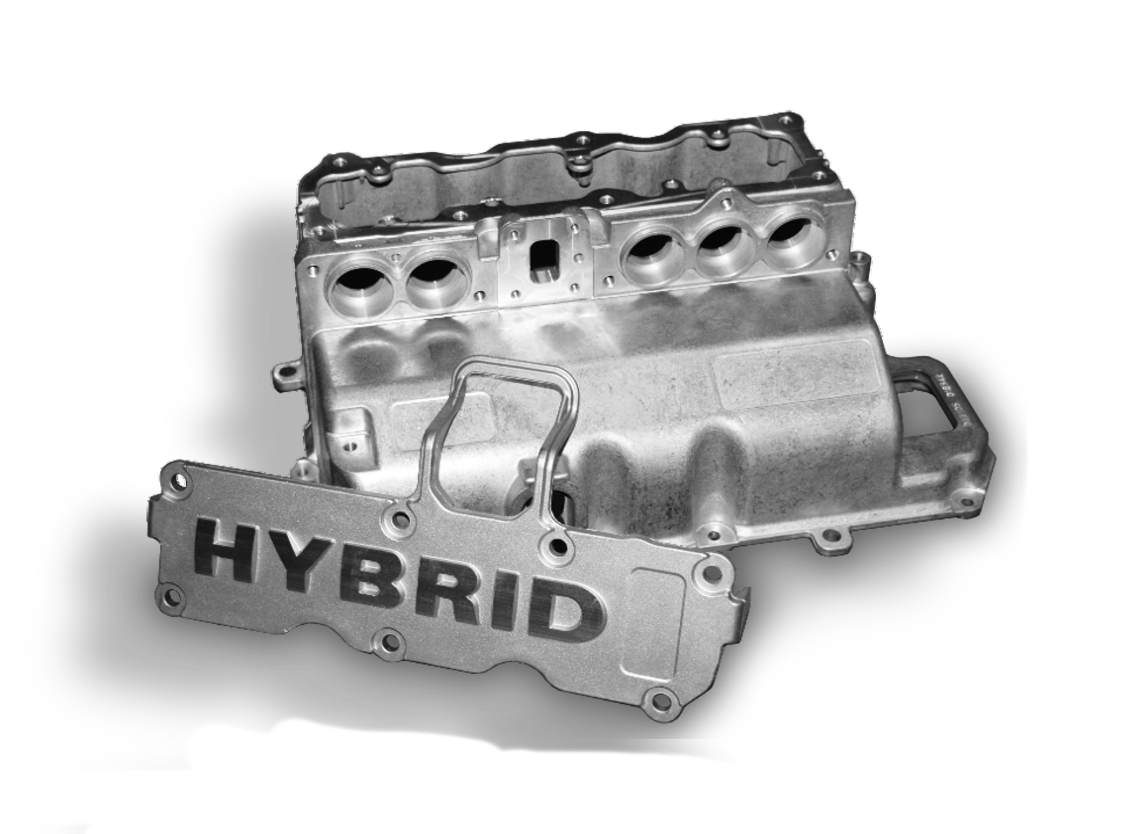

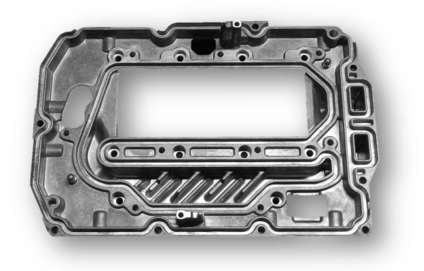

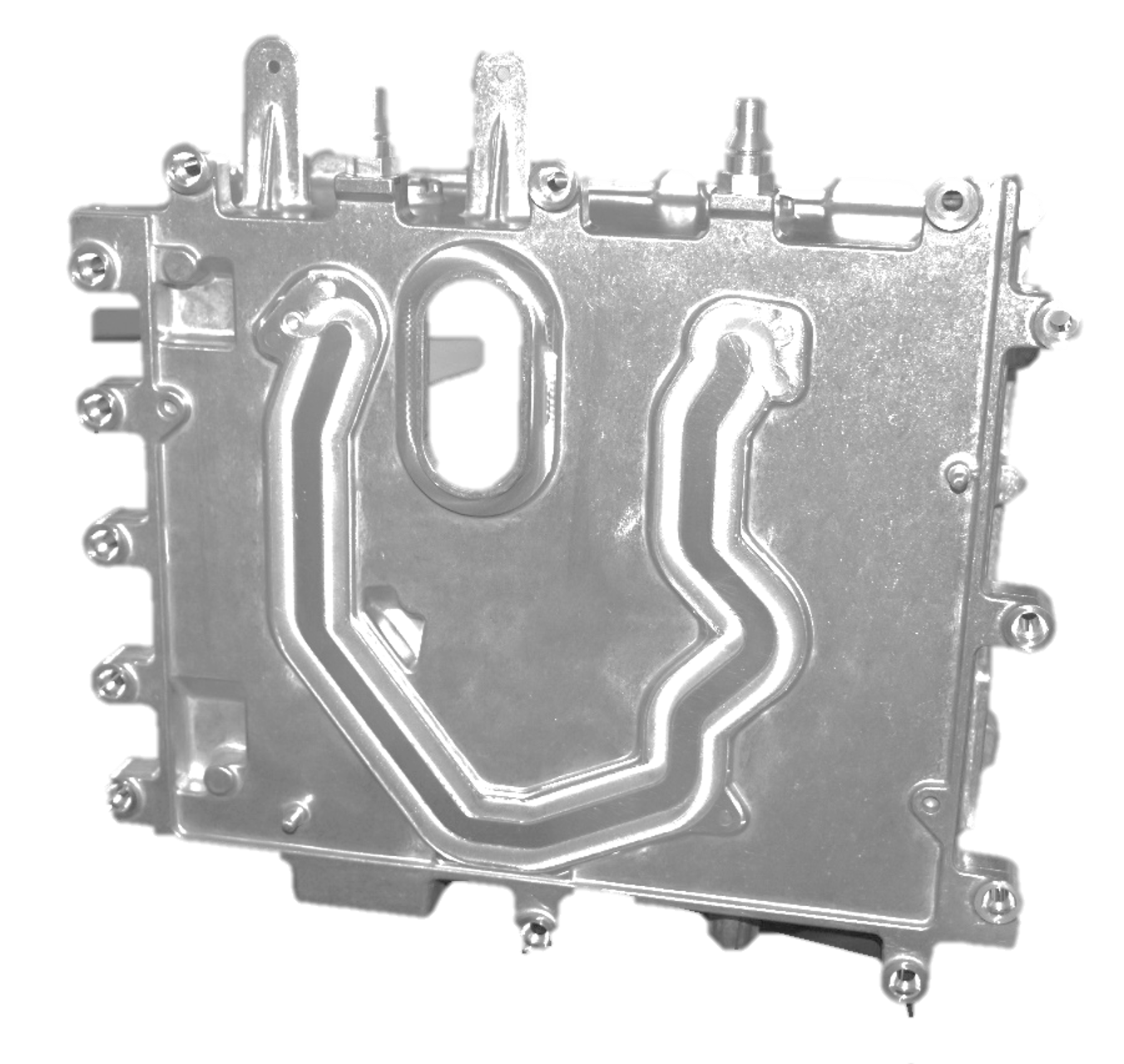

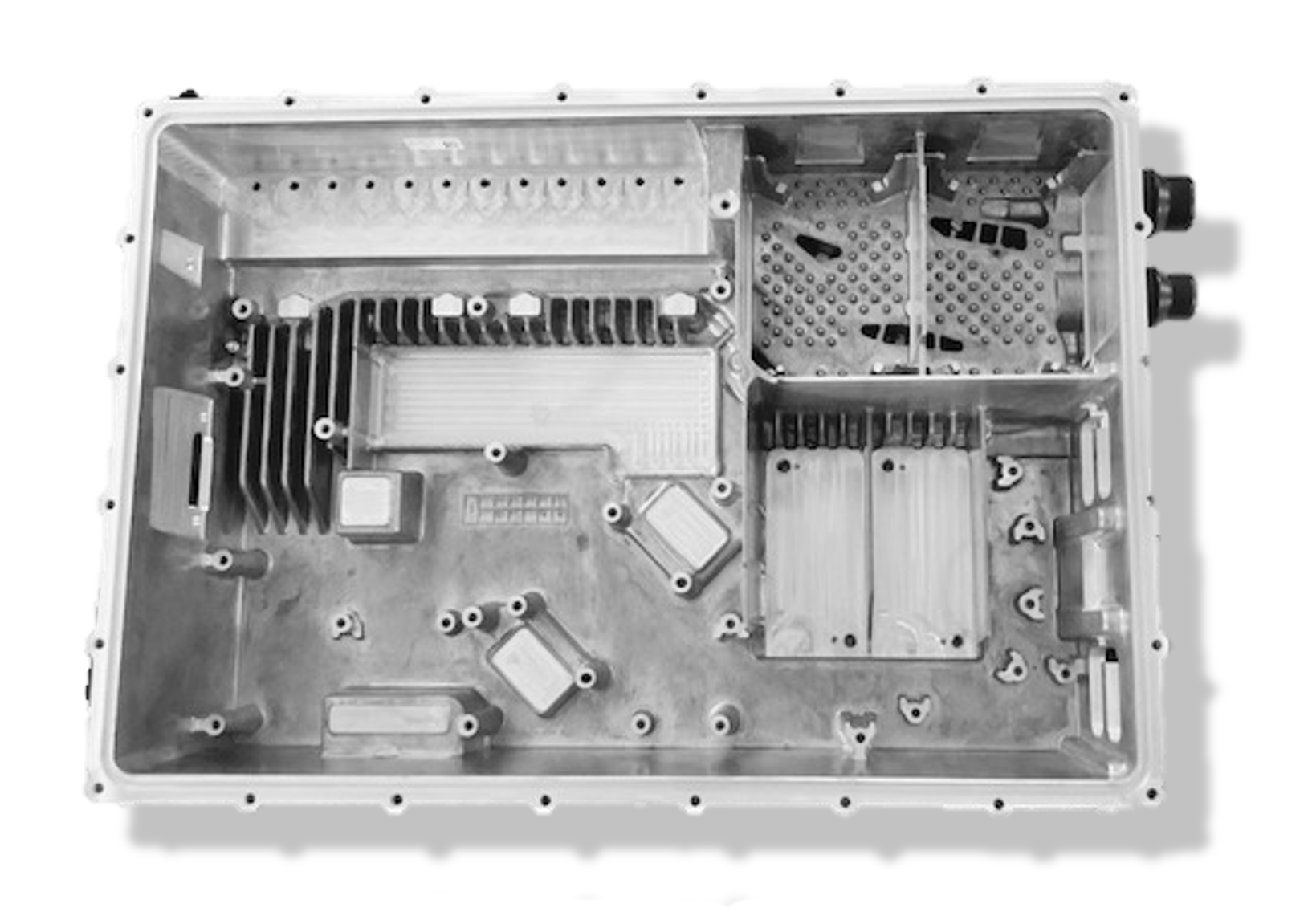

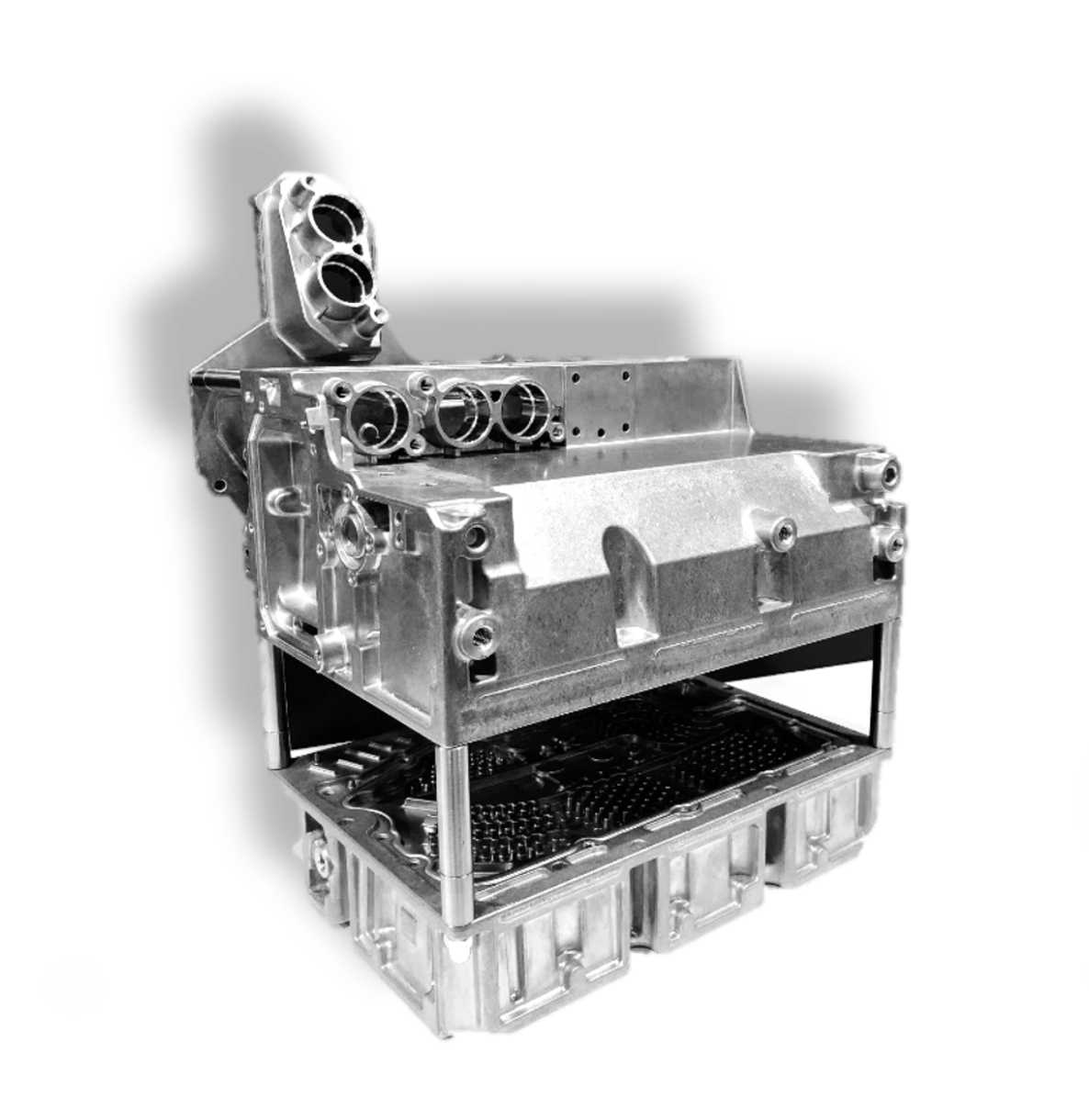

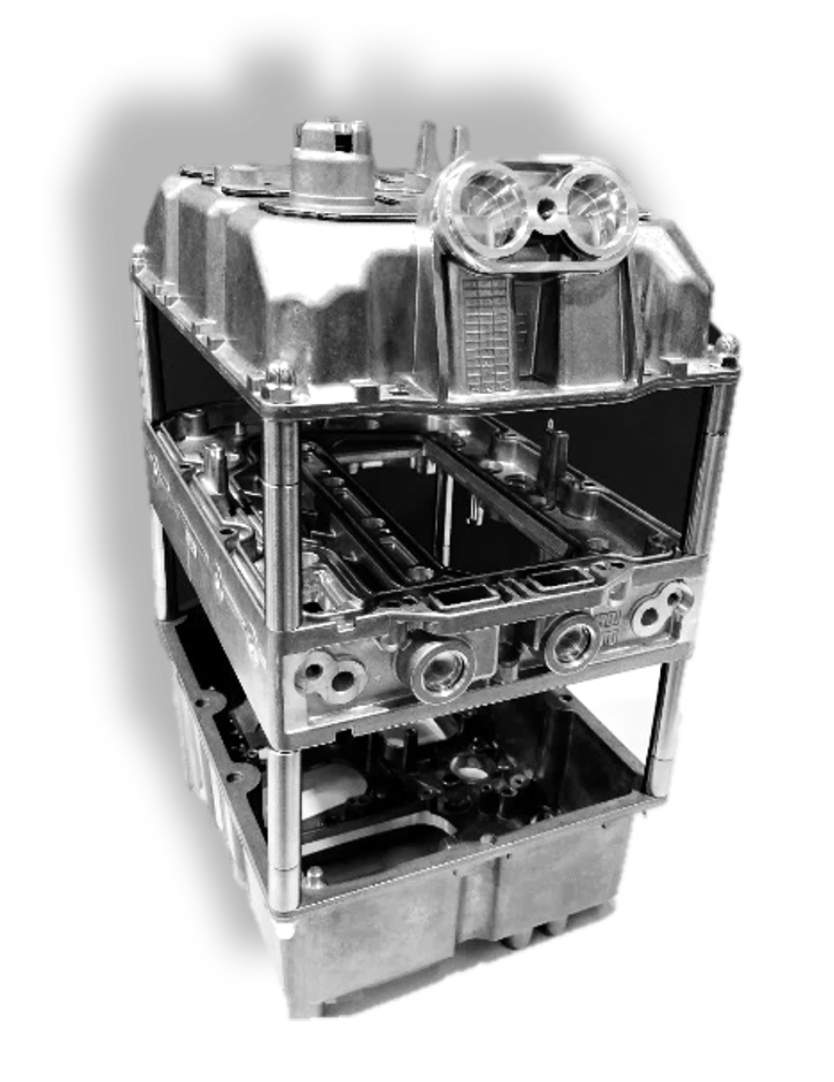

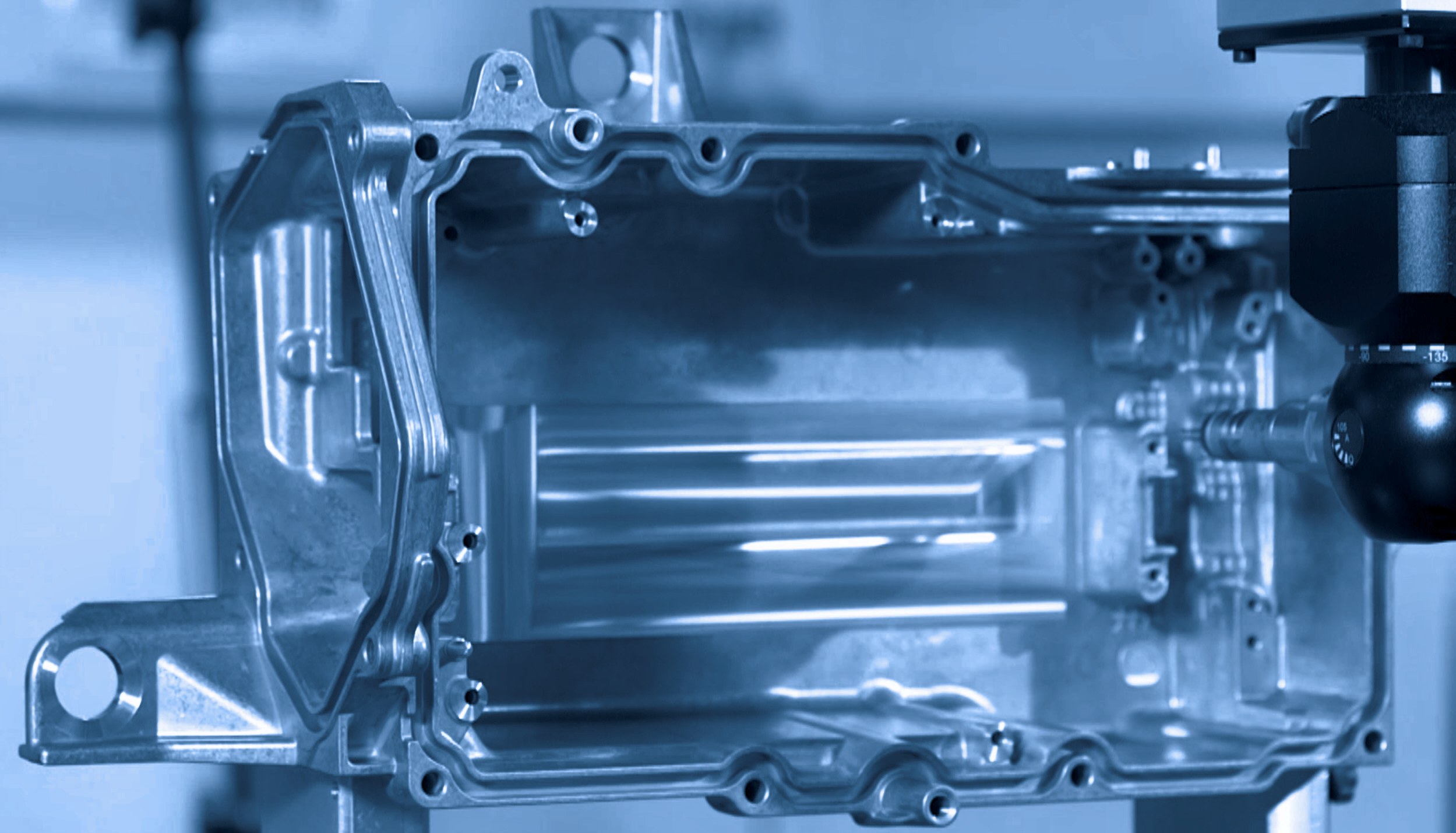

Aluminum alloy die casting for structural and precision components

- 17 automated cells

- Machines from 170 to 2,000 tons

- 7 alloys in production: 46000, 46100, 44300, 47100, 43500, Magsimal, Castasil37, Zama

Machining and finishing

Integrated operations to deliver complete parts

- 50 CNC machining centers with dedicated lines by product family

- 7 washing systems

- Tumbling and sandblasting

- Leak tests in air and helium

- In-line visual and dimensional checks

Quality

Process and product controls

- Spectrometer and X-ray inspections

- Metrology room with 4 CMMs

- Profilometer, roundness and roughness testers

- Cleanliness testing lab

75+

Years in business

3

Production departments

15,000

m² plant area

8+

Alloys in production