Our Company

Over 75 years of aluminum die casting expertise

Today Lucco Borlera is a strategic partner for many European companies. Around 80% of our activity is focused on the Automotive sector, especially electronic control units and mechanical components.

Thanks to a large machinery fleet and skilled personnel, we offer a complete range of products and processes, delivering tailored solutions based on customer needs.

It’s not just die casting and machining: every product results from specific know-how including simultaneous engineering, in-house tool design and manufacturing, residual contamination control, bonding and sealing applications, leak testing, chemical treatments, coating and on-time delivery.

Flexibility, communication and commitment guide our people every day.

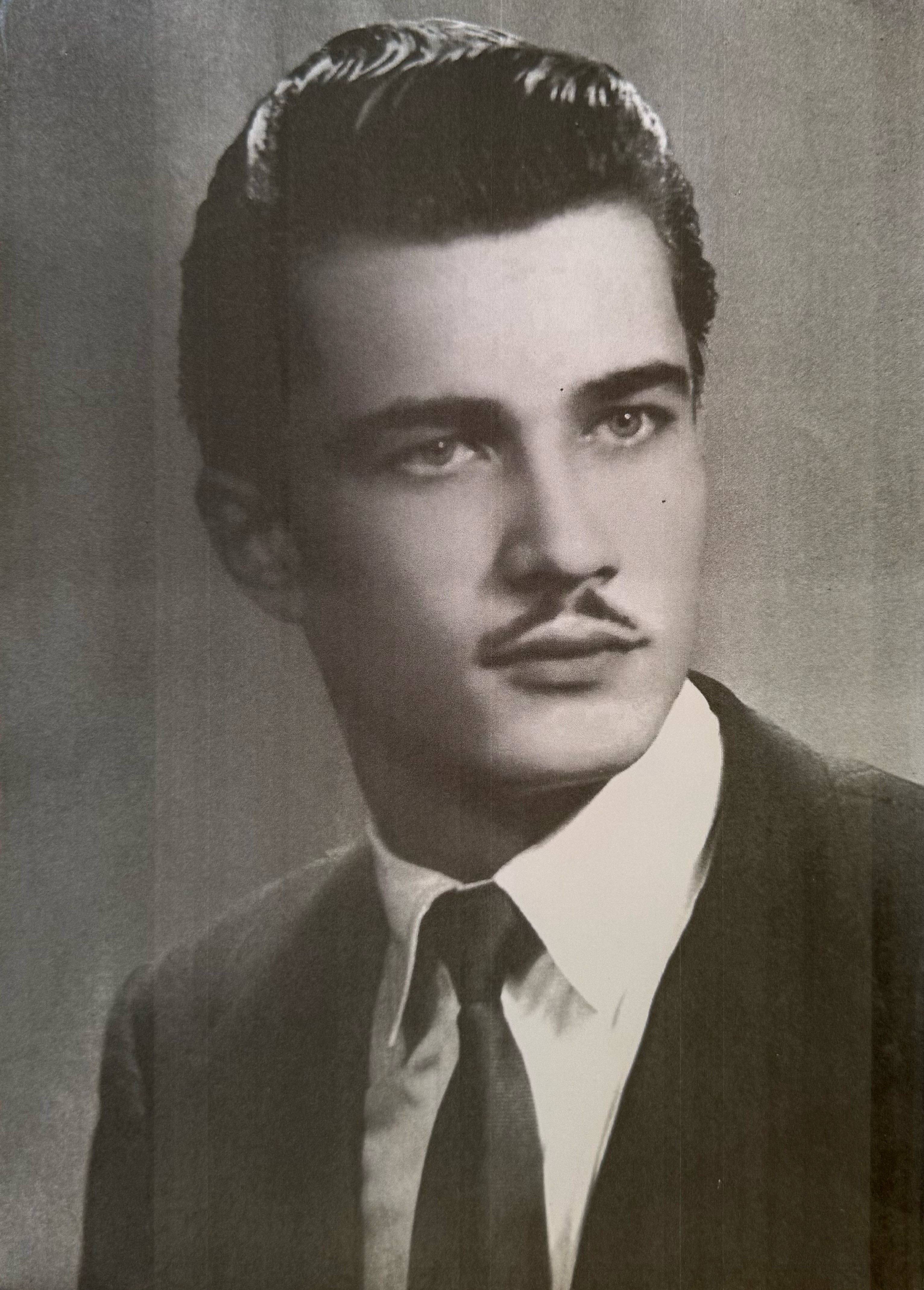

Our history

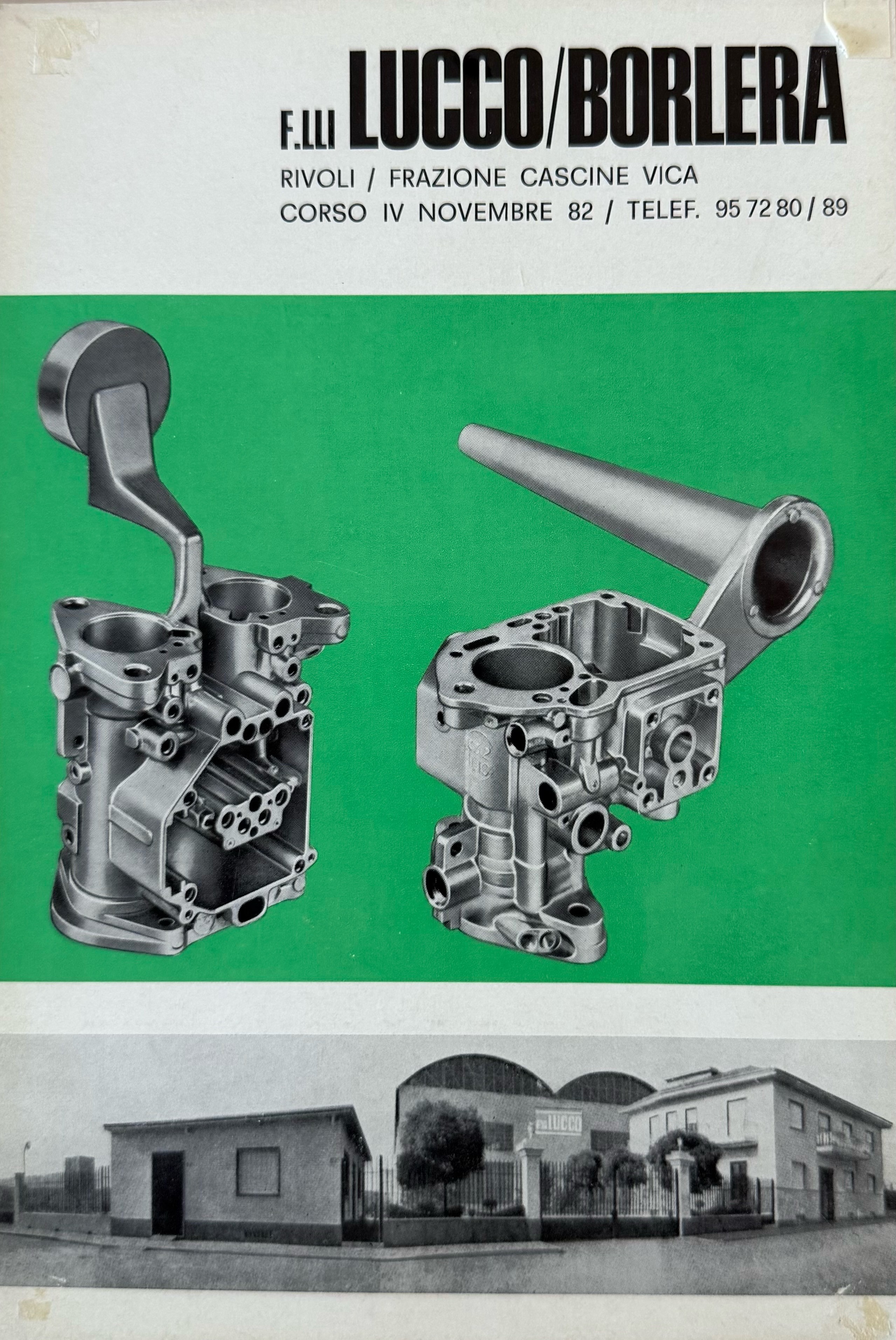

Foundation of F.lli Lucco Borlera. Manufacturing of die casting molds.

Start of aluminum die casting and move to the new Rivoli plant. New European customers.

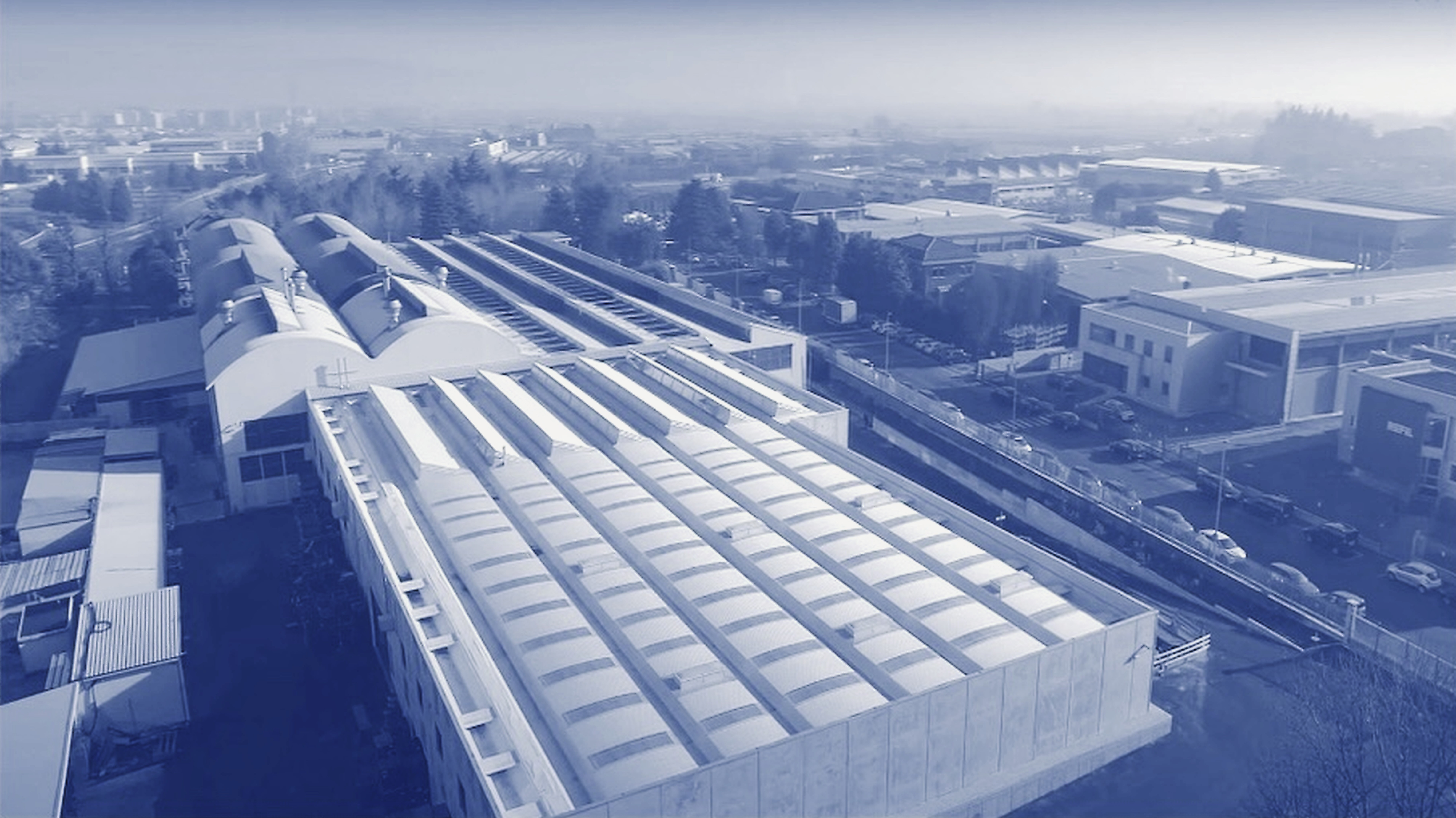

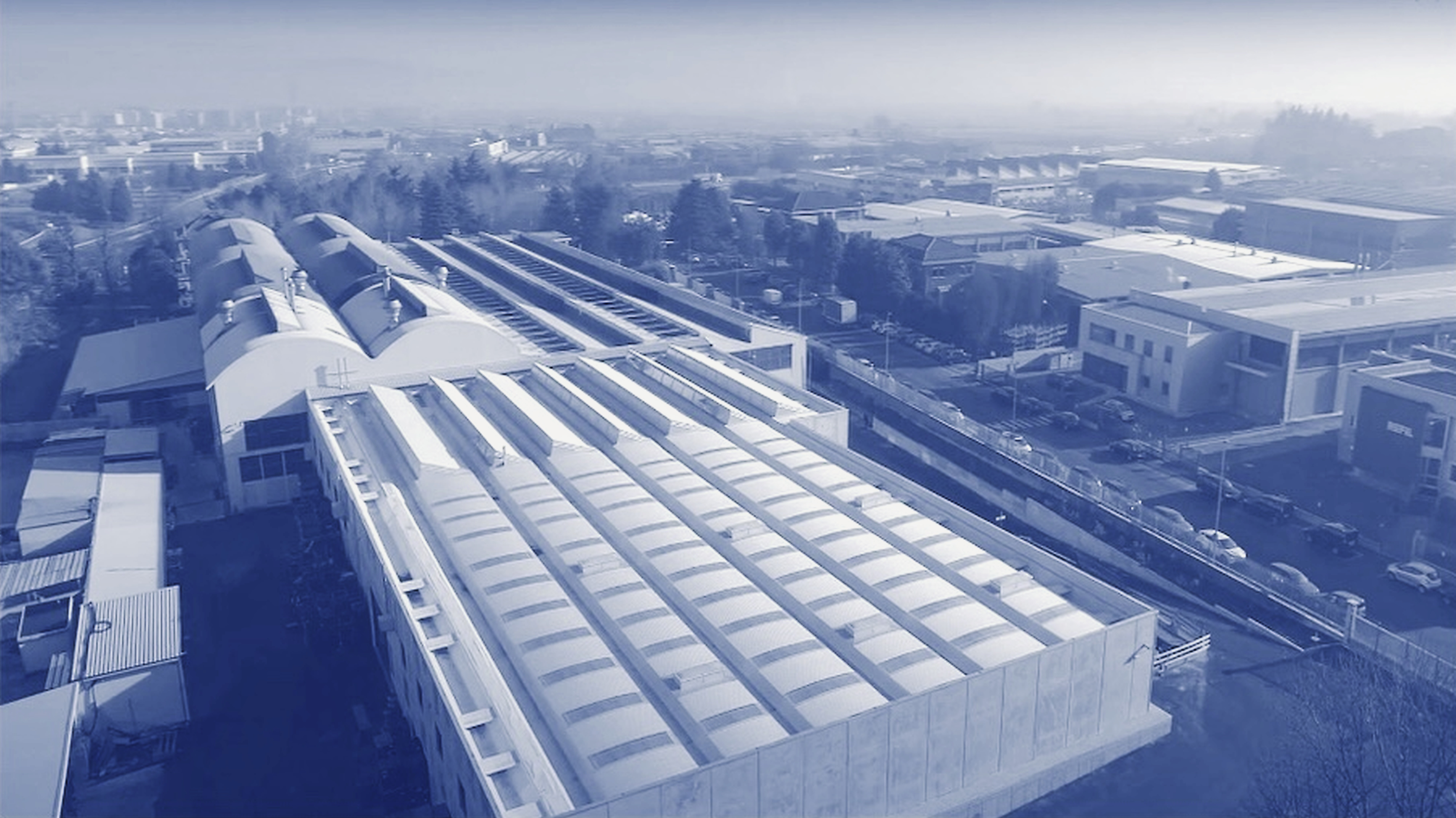

Plant expansion and increased production capacity.

ISO 9001 – Introduction of CNC machining and washing, assembly, air and helium leak testing, with full line traceability.

Investments for sustainability and energy efficiency. Two photovoltaic plants installed (total 400 kW).

IATF certification and plant expansion with die casting presses up to 2000 tons. Separation of machining departments from clean processes; broader product range with larger parts.